Page 6 - Spring 2024

P. 6

EDM Today Magazine

EDM Today Magazine

EDM Today Magazine Need answers for the toughest EDM questions?

You’ve come to the right place!

O-ring Basics

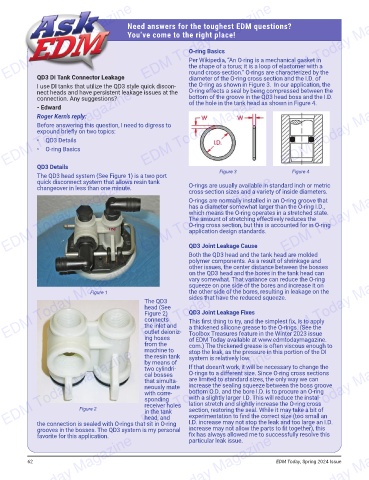

Per Wikipedia, “An O-ring is a mechanical gasket in

round cross-section.” O-rings are characterized by the

QD3 DI Tank Connector Leakage

diameter of the O-ring cross section and the I.D. of

the O-ring as shown in Figure 3. In our application, the

I use DI tanks that utilize the QD3 style quick discon- the shape of a torus; it is a loop of elastomer with a

O-ring effects a seal by being compressed between the

EDM Today Magazine EDM Today Magazine EDM Today Magazine

nect heads and have persistent leakage issues at the

bottom of the groove in the QD3 head boss and the I.D.

connection. Any suggestions?

of the hole in the tank head as shown in Figure 4.

- Edward

Roger Kern’s reply:

Before answering this question, I need to digress to

expound briefl y on two topics:

• QD3 Details

• O-ring Basics

QD3 Details

Figure 4

Figure 3

The QD3 head system (See Figure 1) is a two port

EDM Today Magazine EDM Today Magazine EDM Today Magazine

quick disconnect system that allows resin tank

O-rings are usually available in standard inch or metric

changeover in less than one minute.

cross-section sizes and a variety of inside diameters.

O-rings are normally installed in an O-ring groove that

has a diameter somewhat larger than the O-ring I.D.,

which means the O-ring operates in a stretched state.

The amount of stretching effectively reduces the

O-ring cross section, but this is accounted for in O-ring

application design standards.

QD3 Joint Leakage Cause

Both the QD3 head and the tank head are molded

polymer components. As a result of shrinkage and

EDM Today Magazine EDM Today Magazine EDM Today Magazine

other issues, the center distance between the bosses

on the QD3 head and the bores in the tank head can

vary somewhat. That variance can reduce the O-ring

squeeze on one side of the bores and increase it on

the other side of the bores, resulting in leakage on the

Figure 1

sides that have the reduced squeeze.

The QD3

head (See

QD3 Joint Leakage Fixes

Figure 2)

connects

This fi rst thing to try, and the simplest fi x, is to apply

the inlet and

outlet deioniz-

Toolbox Treasures feature in the Winter 2023 issue

ing hoses

of EDM Today available at www.edmtodaymagazine.

from the a thickened silicone grease to the O-rings. (See the

com.) The thickened grease is often viscous enough to

machine to

EDM Today Magazine EDM Today Magazine EDM Today Magazine

stop the leak, as the pressure in this portion of the DI

the resin tank

system is relatively low.

by means of

If that doesn’t work, it will be necessary to change the

two cylindri-

O-rings to a different size. Since O-ring cross sections

cal bosses

are limited to standard sizes, the only way we can

that simulta-

increase the sealing squeeze between the boss groove

neously mate

bottom O.D. and the bore I.D. is to procure an O-ring

with corre-

with a slightly larger I.D. This will reduce the instal-

sponding

lation stretch and slightly increase the O-ring cross

receiver holes

Figure 2

in the tank

experimentation to fi nd the correct size (too small an

head, and

I.D. increase may not stop the leak and too large an I.D.

the connection is sealed with O-rings that sit in O-ring

increase may not allow the parts to fi t together), this

grooves in the bosses. The QD3 system is my personal section, restoring the seal. While it may take a bit of

fi x has always allowed me to successfully resolve this

favorite for this application.

EDM Today Magazine

EDM Today Magazine EDM Today Magazine EDM Today, Spring 2024 Issue

particular leak issue.

62