Page 3 - Summer 2024

P. 3

EDM Today Magazine EDM Today Magazine EDM Today Magazine

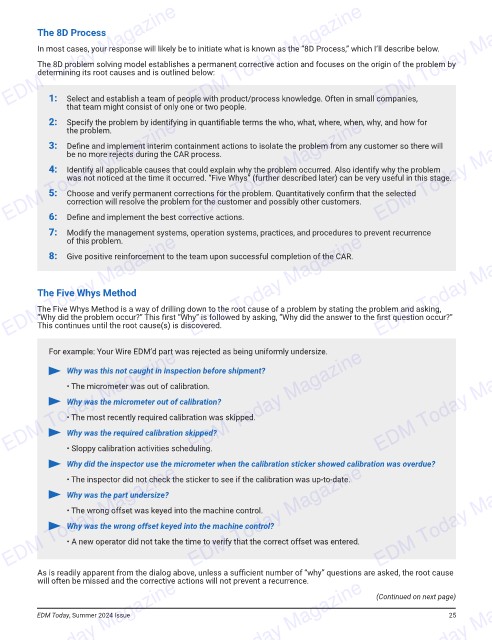

The 8D Process

In most cases, your response will likely be to initiate what is known as the “8D Process,” which I’ll describe below.

The 8D problem solving model establishes a permanent corrective action and focuses on the origin of the problem by

determining its root causes and is outlined below:

1: Select and establish a team of people with product/process knowledge. Often in small companies,

that team might consist of only one or two people.

2: Specify the problem by identifying in quantifi able terms the who, what, where, when, why, and how for

EDM Today Magazine EDM Today Magazine EDM Today Magazine

the problem.

3: Defi ne and implement interim containment actions to isolate the problem from any customer so there will

be no more rejects during the CAR process.

4: Identify all applicable causes that could explain why the problem occurred. Also identify why the problem

was not noticed at the time it occurred. “Five Whys” (further described later) can be very useful in this stage.

5: Choose and verify permanent corrections for the problem. Quantitatively confi rm that the selected

correction will resolve the problem for the customer and possibly other customers.

6: Defi ne and implement the best corrective actions.

7: Modify the management systems, operation systems, practices, and procedures to prevent recurrence

EDM Today Magazine EDM Today Magazine EDM Today Magazine

of this problem.

8: Give positive reinforcement to the team upon successful completion of the CAR.

The Five Whys Method

The Five Whys Method is a way of drilling down to the root cause of a problem by stating the problem and asking,

“Why did the problem occur?” This fi rst “Why” is followed by asking, “Why did the answer to the fi rst question occur?”

This continues until the root cause(s) is discovered.

For example: Your Wire EDM’d part was rejected as being uniformly undersize.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Why was this not caught in inspection before shipment?

• The micrometer was out of calibration.

Why was the micrometer out of calibration?

• The most recently required calibration was skipped.

Why was the required calibration skipped?

Why did the inspector use the micrometer when the calibration sticker showed calibration was overdue?

• Sloppy calibration activities scheduling.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

• The inspector did not check the sticker to see if the calibration was up-to-date.

Why was the part undersize?

• The wrong offset was keyed into the machine control.

Why was the wrong offset keyed into the machine control?

• A new operator did not take the time to verify that the correct offset was entered.

As is readily apparent from the dialog above, unless a suffi cient number of “why” questions are asked, the root cause

will often be missed and the corrective actions will not prevent a recurrence.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

(Continued on next page)

25

EDM Today, Summer 2024 Issue