Page 6 - Summer 2024

P. 6

EDM Today Magazine EDM Today Magazine EDM Today Magazine

MANUAL WIRE THREADING

Threading a Broken Wire

Manual threading is still often utilized either for the mul-

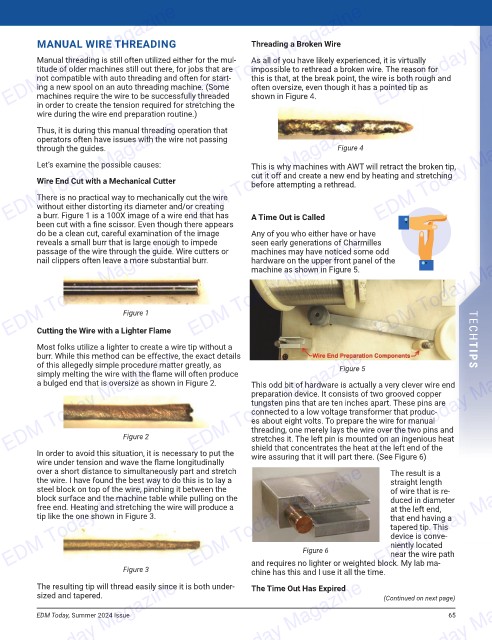

As all of you have likely experienced, it is virtually

titude of older machines still out there, for jobs that are

impossible to rethread a broken wire. The reason for

not compatible with auto threading and often for start-

this is that, at the break point, the wire is both rough and

ing a new spool on an auto threading machine. (Some

machines require the wire to be successfully threaded

shown in Figure 4.

in order to create the tension required for stretching the

wire during the wire end preparation routine.) often oversize, even though it has a pointed tip as

EDM Today Magazine EDM Today Magazine EDM Today Magazine

Thus, it is during this manual threading operation that

operators often have issues with the wire not passing

Figure 4

through the guides.

Let’s examine the possible causes:

This is why machines with AWT will retract the broken tip,

This is why machines with AWT will retract the broken tip,

cut it off and create a new end by heating and stretching

Wire End Cut with a Mechanical Cutter

before attempting a rethread.

There is no practical way to mechanically cut the wire

without either distorting its diameter and/or creating

a burr. Figure 1 is a 100X image of a wire end that has

been cut with a fi ne scissor. Even though there appears A Time Out is Called

do be a clean cut, careful examination of the image Any of you who either have or have

EDM Today Magazine EDM Today Magazine EDM Today Magazine

reveals a small burr that is large enough to impede

seen early generations of Charmilles

passage of the wire through the guide. Wire cutters or

machines may have noticed some odd

nail clippers often leave a more substantial burr.

hardware on the upper front panel of the

machine as shown in Figure 5.

Figure 1

Cutting the Wire with a Lighter Flame

Most folks utilize a lighter to create a wire tip without a Figure 5 TECHTIPS

EDM Today Magazine EDM Today Magazine EDM Today Magazine

burr. While this method can be effective, the exact details

of this allegedly simple procedure matter greatly, as

simply melting the wire with the fl ame will often produce

a bulged end that is oversize as shown in Figure 2.

This odd bit of hardware is actually a very clever wire end

This odd bit of hardware is actually a very clever wire end

preparation device. It consists of two grooved copper

tungsten pins that are ten inches apart. These pins are

connected to a low voltage transformer that produc-

es about eight volts. To prepare the wire for manual

threading, one merely lays the wire over the two pins and

threading, one merely lays the wire over the two pins and

Figure 2

stretches it. The left pin is mounted on an ingenious heat

shield that concentrates the heat at the left end of the

In order to avoid this situation, it is necessary to put the

wire assuring that it will part there. (See Figure 6)

wire under tension and wave the fl ame longitudinally stretches it. The left pin is mounted on an ingenious heat

EDM Today Magazine EDM Today Magazine EDM Today Magazine

over a short distance to simultaneously part and stretch

The result is a

the wire. I have found the best way to do this is to lay a

straight length

steel block on top of the wire, pinching it between the

of wire that is re-

block surface and the machine table while pulling on the

duced in diameter

free end. Heating and stretching the wire will produce a

at the left end,

tip like the one shown in Figure 3.

that end having a

tapered tip. This

device is conve-

niently located

Figure 6

near the wire path

Figure 3 and requires no lighter or weighted block. My lab ma-

chine has this and I use it all the time.

EDM Today Magazine EDM Today Magazine EDM Today Magazine

The resulting tip will thread easily since it is both under-

The Time Out Has Expired

sized and tapered.

(Continued on next page)

65

EDM Today, Summer 2024 Issue